Sinking EDM - Wire cutting - Micro drilling

We believe that every EDM need will find its solution at Tool Precis

European leader in Extreme EDM with more than 60 years of experience, we push back the limits of conventional machining to deliver flawless mechanical parts within your deadlines.

Why consult us ?

Tell us about your project

contact us

Who are we ?

Tool Precis is an SME created in 1960 with the main activity of making special machines.

The company then quickly specialized in the field of electroerosion

by dealing with all the needs related to this new technology.

Tool Precis brings you the solution to treat materials that are too hard or fragile with high precision:

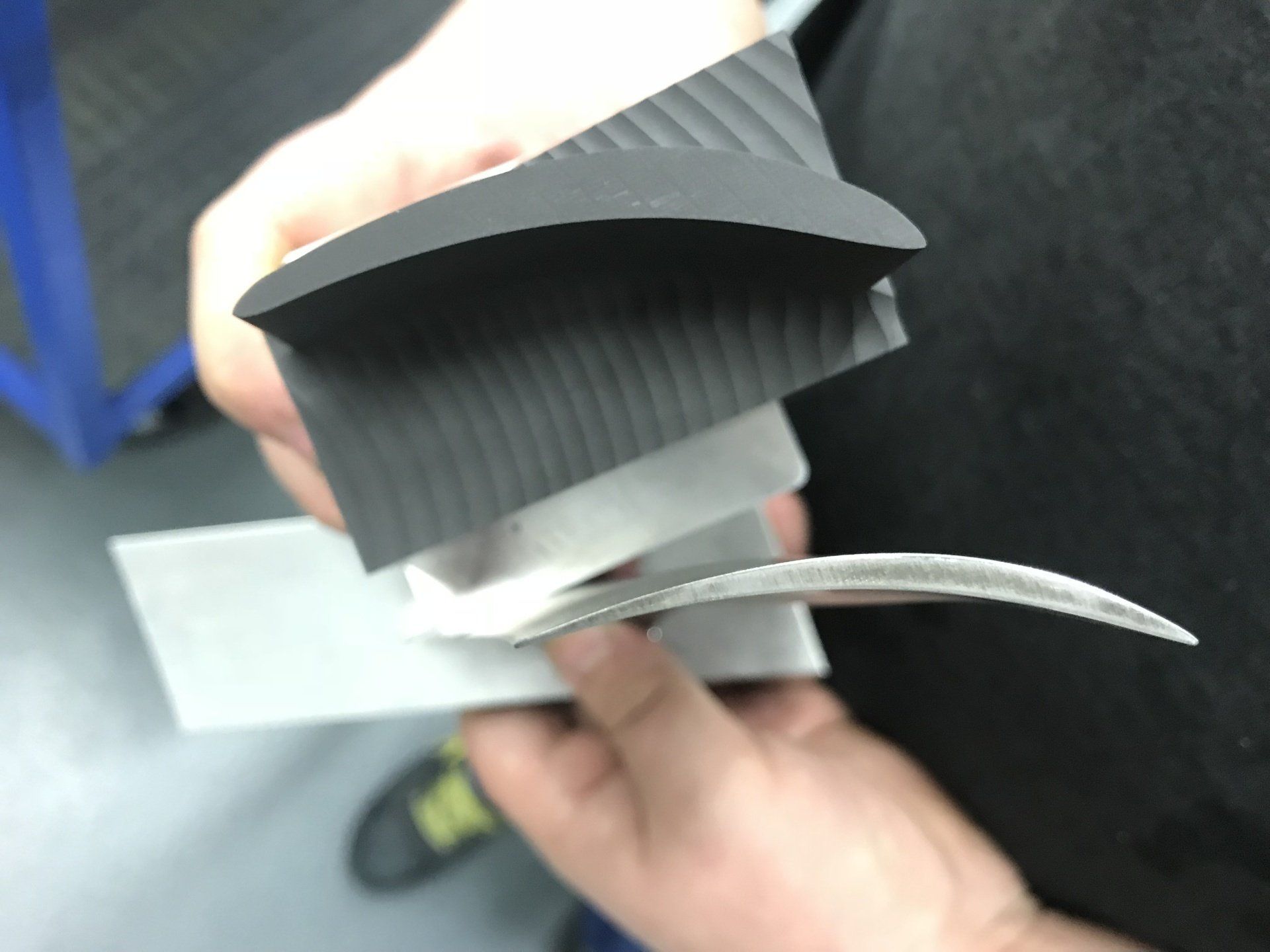

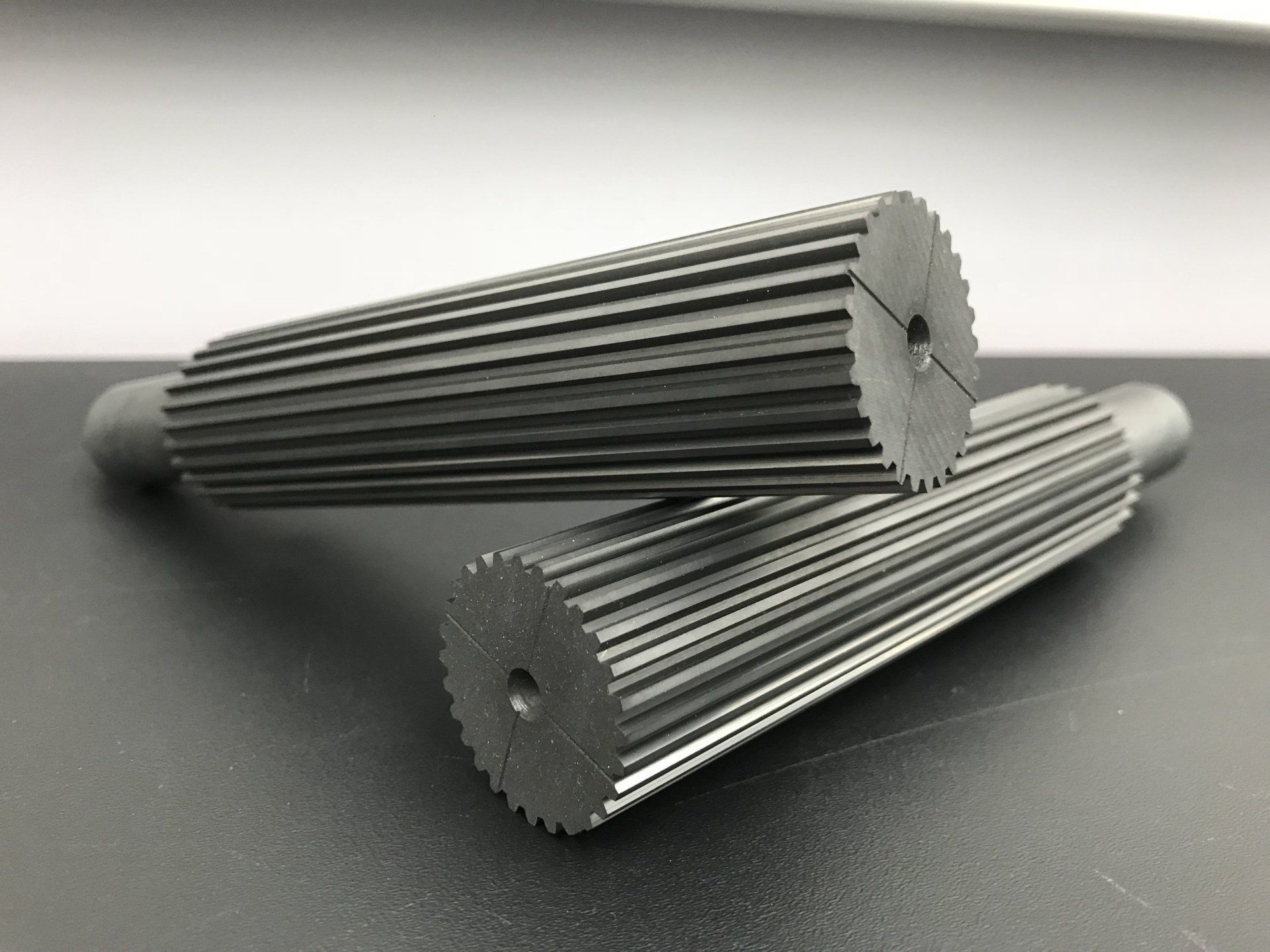

Sinking, wire cutting and micro drilling on all conductive materials.

(Super Alloy INCO 718, Titanium, monocrystalline, Aluminum, Stainless steel, Steel, Carbide…)

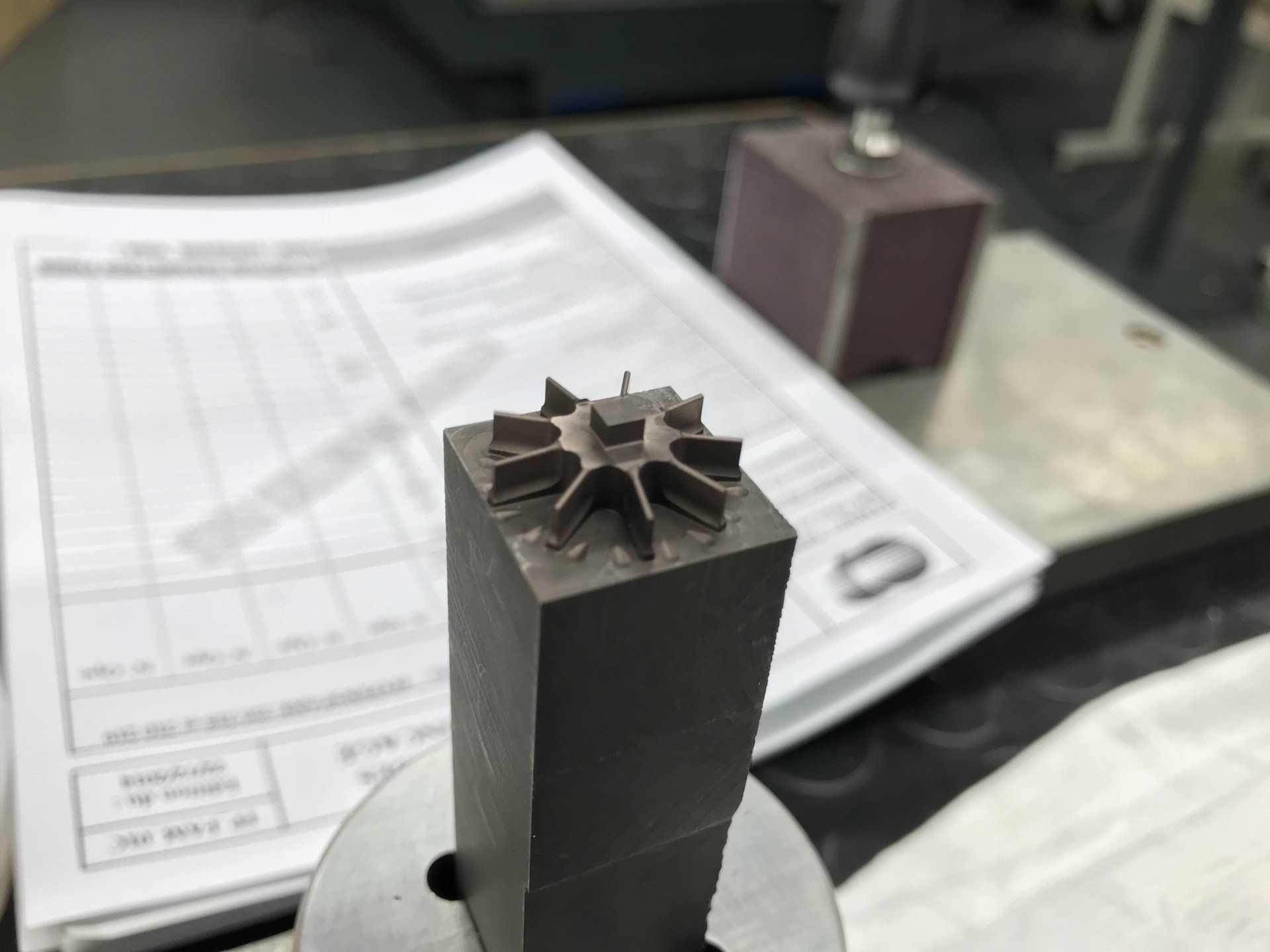

Study and production of electrodes and tools

Wire machining or sinking

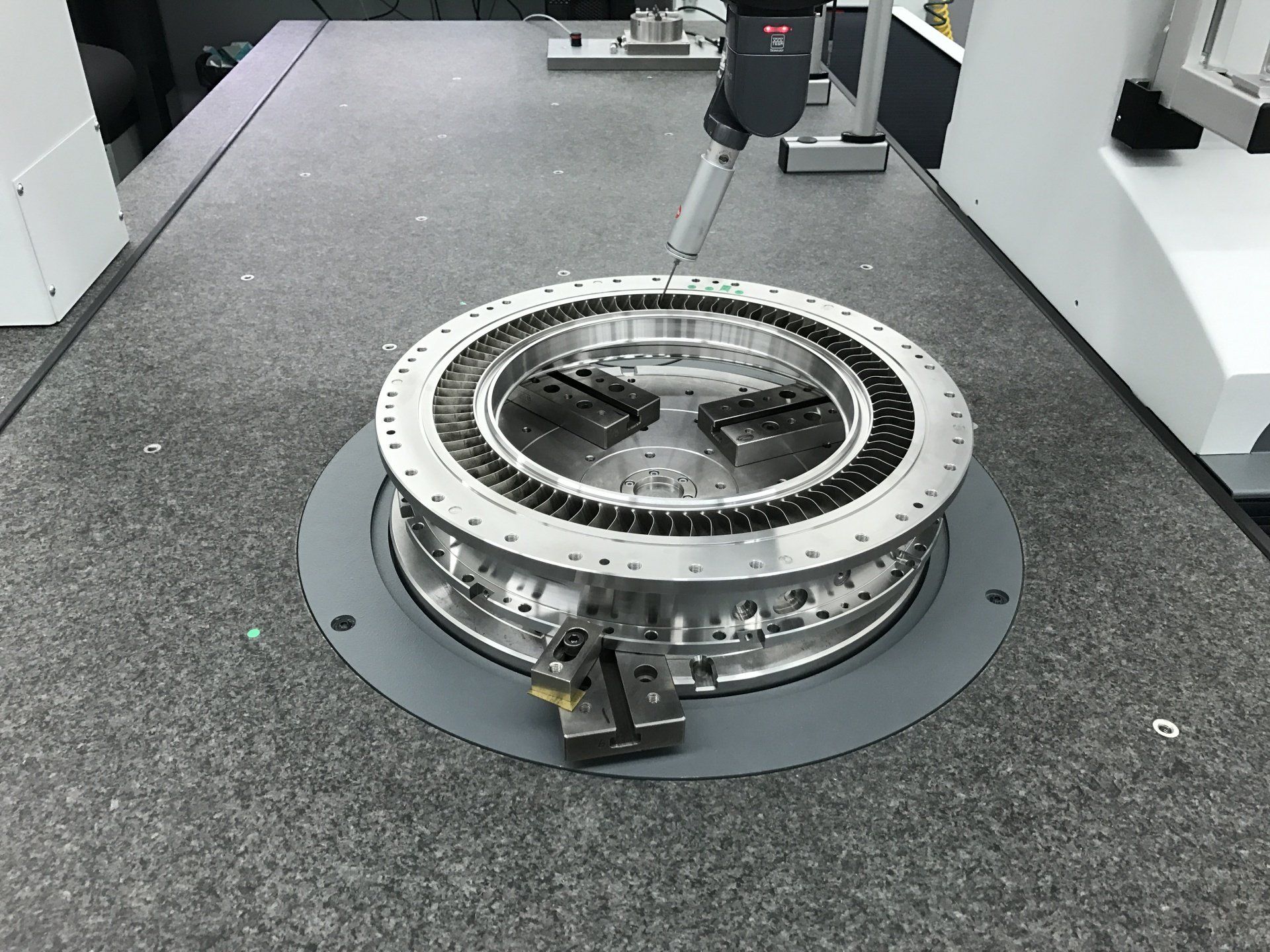

Quality Control

OUR WORKSHOP

Our team consists only of highly qualified and autonomous technicians.

Precise Tool uses the Spare method. The objective is simple: deliver customers in record time while reducing logistics costs.

How do we work?

3D model of the room

We make a 3D model of your part from the plans you send us.

Sinking or Wire Cutter

We then select the most appropriate method to shape the part you need.

Design of CAD programs

We create the tools necessary to work perfectly on your part and then we carry out its machining.

Control and delivery

Once the part has been produced, we carry out a check to verify that it is 100% compliant and we send it as soon as possible.

Our quality commitment

ISO 9001 and EN9100 standards

Bureau Veritas certification.

Shades mastered

We work with conductive alloys without distinction of hardness, Steel, Hardened steel, Refractory stainless steel, Monocrystalline, Composites.

NADCAP Accreditation

100% of the machine park.

Certification Clients

SAFRAN and Collins AEROSPACE certified.

EDM, A PRECISE TOOL: EXTREME EROSION

Legal Notice

Privacy Policy